Lower CO2 impact

Reduce your carbon footprint

- Reduced environmental impact from storage and freight. Primoreels® pallets contain more than twice the number of lids.

- Thinner lids. Primoreels® systems operate with metalized PET foil as thin as 23 or 36 microns.

- Eliminate snap-on cover lids. Primoreels® PET lids have a superior puncture resistance so one lid is enough.

- Significantly less waste. With Primoreels® the only waste is the cardboard reel and sealed delivery bag.

Cut your carbon impact

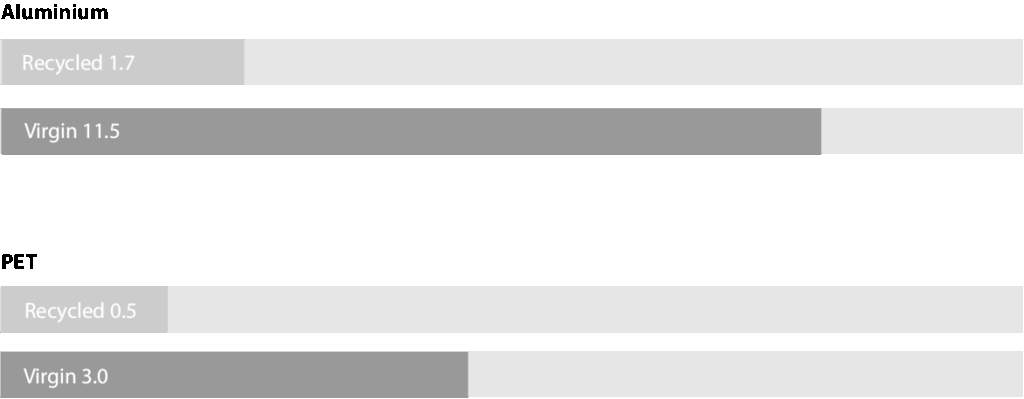

CO2 emissions when producing PET lids are significantly lower than for aluminium lids

Note: All figures are kilograms carbon dioxide equivalents per kilogram of material produced (kg CO2/kg). The bars compare the carbon intensity of the material when produced from virgin resources or from recycled materials. Sources: DEFRA, Fraunhofer Insistute.

- Primoreels® minimize the skeleton waste material. Rollstock contains waste material of up to 56% for Ø95 mm cups.

- Primoreels® systems reduce skeleton waste to less than 20%.

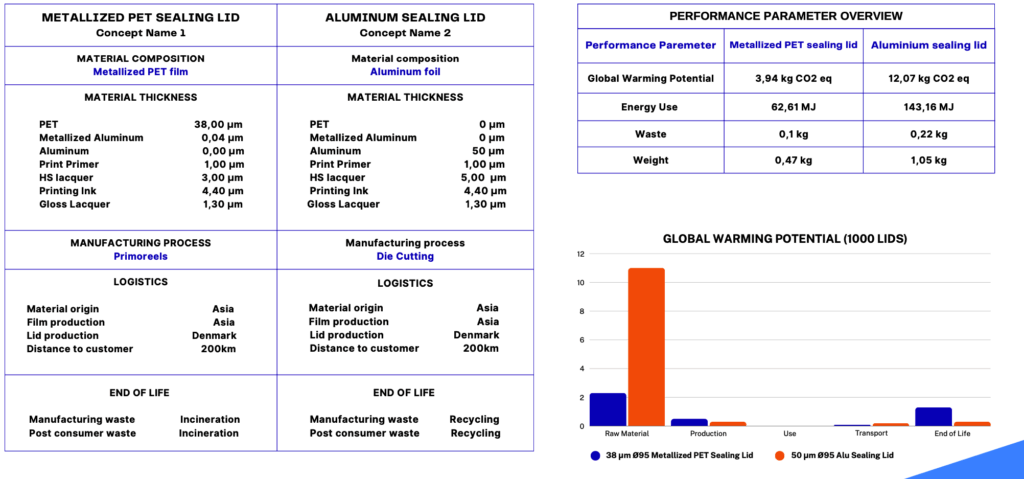

Global Warming Potential Analysis

Metallized PET Sealing Lid vs Aluminum Sealing Lid

Metallized PET sealing lid compared to a typical aluminum sealing lid for Ø95 yogurt containers.

This statement presents the results of a global warming potential analysis of Primoreels A/S’ metallized PET sealing lid compared to a typical aluminum sealing lid for Ø95 yogurt containers.

The screening compares global warming potential, energy consumption, product weight, and waste.

The calculations for the metallized PET sealing lid are based on an LCA where the calculations for the Aluminum Sealing Lid merely are indicative based on oversimplifications. Thus, the comparison between the two lids are only indicative as well. Deeper analysis would be necessary to determine the exact difference.

METALLIZED PET SEALING LID

Company: Primoreels A/S

Material: Metallized PET

Size: Ø95

Thickness: 38 μm

Area: 7789 mm

ALUMINUM SEALING LID

Company: Any die cut producer

Material: Aluminum (60% recycled)

Size: Ø95

Thickness: 50 μm

Area: 7631 mm

Product configurator

You as a client is central to our business

As our client, your needs are our central focus of attention. We aim to offer flexible and user-friendly solutions that suit your needs, resources, and capacity. Getting started using sealable lids as part of your packaging process is as user-friendly as can be.

We’ve made sure, that the transition to using this new method of lids for packaging is as smooth as possible – because we know, that ease of use and less friction in changing production methods is central to your production!

Contact Primoreels today to hear more about sealable lids

Get in touch with us today to hear more about how sealable lids can be a beneficial part of your packaging process

– we look forward to hearing from you!

Our products

We offer a wide range of products

Met. PET with HS lacquer

The unique Primoreels® technology allows our clients to use sealable lids in a quality as thin as 23 microns PET material. For an improved quality experience on larger cup formats…

Met. PET CoEX

The unique Primoreels® technology allows our clients to use sealable lids in a quality as thin as 23 microns material. For an improved quality experience on larger cup formats…

Walki®Lid – Paperbased

Primoreels® offers a material structure of coated paper and CoEx sealing layer from Walki. The material is beneficial for e.g. dry products, and offers a unique and authentic look to the final…