Better hygiene and food safety

The Primoreels® system are implemented with a UV treatment tunnel as a standard, in which the lids can be treated easily and inexpensively. When comparing with treatment of traditional die cut lids from stacks – the solution available for die cut lids is very expensive, and not as effective, due to less available time for radiation of the lids. Especially on rotary filling machines sealable die cut lid sterilization is difficult due to the limited space available for treating the lids. Thanks to the treatment tunnel Primoreels® can offer effective treatment solutions for linear high capacity filling machines as well as rotary filling machines.

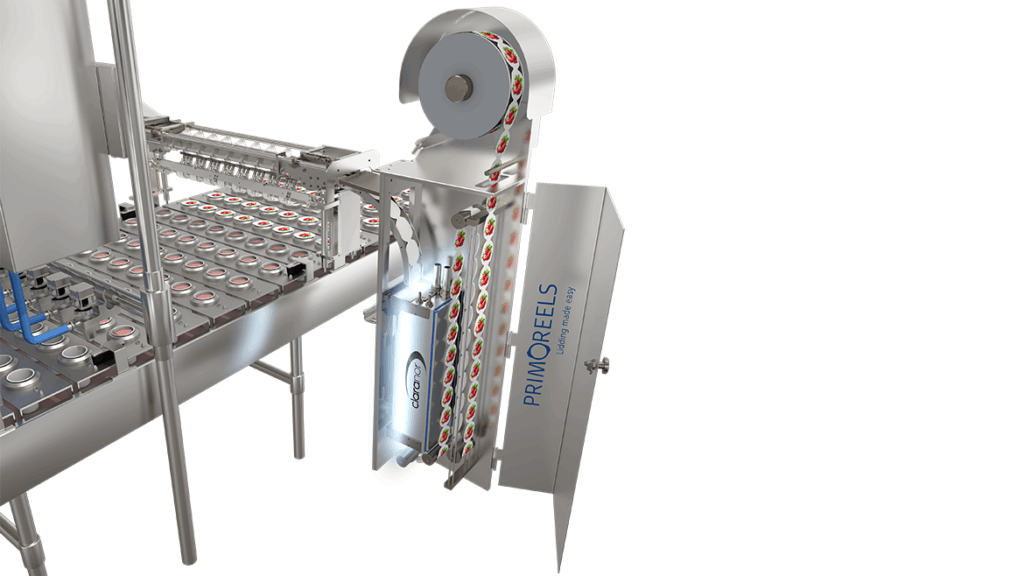

For the high capacity machines or very demanding applications where specially fragile and/or cold filled products are produced – ultra clean standards are a most. For these applications Primoreels® offer a pulsed light treatment by the “Claranor” pulsed light technology. The combination of the Primoreels lidding foils and the claranor pulsed light technology makes it possible to achieve log reductions in the level of log4.

Primoreels® offers less manual work for the operators in the dairies. One reel can contain + 40.000 pcs. of sealable lids, which is mounted in the machine in less than 1 minute.

High hygienic system with “no manual handling throughout the production chain”

See our brochures

You as a client is central to our business

As our client, your needs are our central focus of attention. We aim to offer flexible and user-friendly solutions that suit your needs, resources, and capacity. Getting started using sealable lids as part of your packaging process is as user-friendly as can be.

We’ve made sure, that the transition to using this new method of lids for packaging is as smooth as possible – because we know, that ease of use and less friction in changing production methods is central to your production!

Contact Primoreels today to hear more about sealable lids

Get in touch with us today to hear more about how sealable lids can be a beneficial part of your packaging process

– we look forward to hearing from you!

Our products

We offer a wide range of products

Met. PET with HS lacquer

The unique Primoreels® technology allows our clients to use sealable lids in a quality as thin as 23 microns PET material. For an improved quality experience on larger cup formats…

Met. PET CoEX

The unique Primoreels® technology allows our clients to use sealable lids in a quality as thin as 23 microns material. For an improved quality experience on larger cup formats…

Walki®Lid – Paperbased

Primoreels® offers a material structure of coated paper and CoEx sealing layer from Walki. The material is beneficial for e.g. dry products, and offers a unique and authentic look to the final…